AccuShot precision seed fertiliser

The best start for each seed

- February 17, 2023

Reduces fertiliser costs, improves plant health, protects the environment.

The Challenge

Can we reduce fertiliser use without sacrificing food production?

The world has a fertiliser problem. On the one hand, we need fertiliser to grow enough food to feed everybody. On the other hand, using too much fertiliser can damage the environment. To make things worse, a shortage of nitrogen has driven up prices. The repercussions affect farmers and consumers everywhere. So what can be done to help? There is probably no single answer for an issue that combines environmental, economic, political factors on a world scale. But technological ingenuity can make a difference for farmers.

What are the benefits of the AccuShot application system?

- Reduces fertiliser costs by only giving each seed an individual dose instead of applying fertiliser the entire length of the furrow

- Protects the environment by not applying unneeded fertiliser

- Secures food production – no reduction in yield

- Improves plant health by applying the right nutrient dose in the right place for maximum crop yield

The Solution

Dose per seed not per hectare

We already have the technology to plant seeds with the utmost precision in depth, spacing and row patterns. So why not do the same with the fertiliser? The idea is to spoon-feed each seed with a predefined dose of liquid starter for early uptake and maximum growth potential.

Most agronomists agree that applying a starter can improve nutrient uptake, encourage early growth, lead to stronger stalks and bigger ears, even result in lower moisture at harvest time. By placing the exact does in the right place you can maintain or increase yield while reducing input costs.

Introducing the Great Plains Accu-Shot

Replacing waste with precision

Until now, starter application has been a bit challenging. You can simply broadcast the starter. You can apply it along the entire length of the row 5 cm beside and 5 cm below the seed. Or apply it in a band on the surface near the row. You can also place it in-row with a seed firmer. All of these methods are fertilizing per hectare instead of per seed.

The AccuShot system lets you use liquid fertiliser more efficiently by giving only the exact dose to each seed. Accuracy is the key. Instead of spreading the nutrient all over the soil, or even dribbling it along the planting row, the AccuShot system places a precise amount of starter treatment in a precise place in relation to each seed. Each plant gets the food it needs to grow healthily, and no fertiliser is wasted, which is good for the environment and for your budget.

Maize meets precision

There are good reasons for treating maize with precision. The valuable calories that maize delivers comes from nitrogen. If the plant does not have enough nitrogen during its growth phase, crop yields will suffer. But you can’t just spread hectares and hectares of land with nitrogen. It is expensive and harms soil fertility.

Phosphorus is also important for the health of young maize plants. With traditional dribble application as little as 25% of the phosphorus reaches the plant’s feeder roots. The rest is waste – expensive waste.

A three-year study by B&M Crop Consulting showed consistent results when placing starter 2 cm from seed with AccuShot. There was an increase of about 670 kg/ha compared to the control field without starter. In comparison to a dribble application of starter, the AccuShot field needed 75% less starter and produced about 330 kg/ha more.

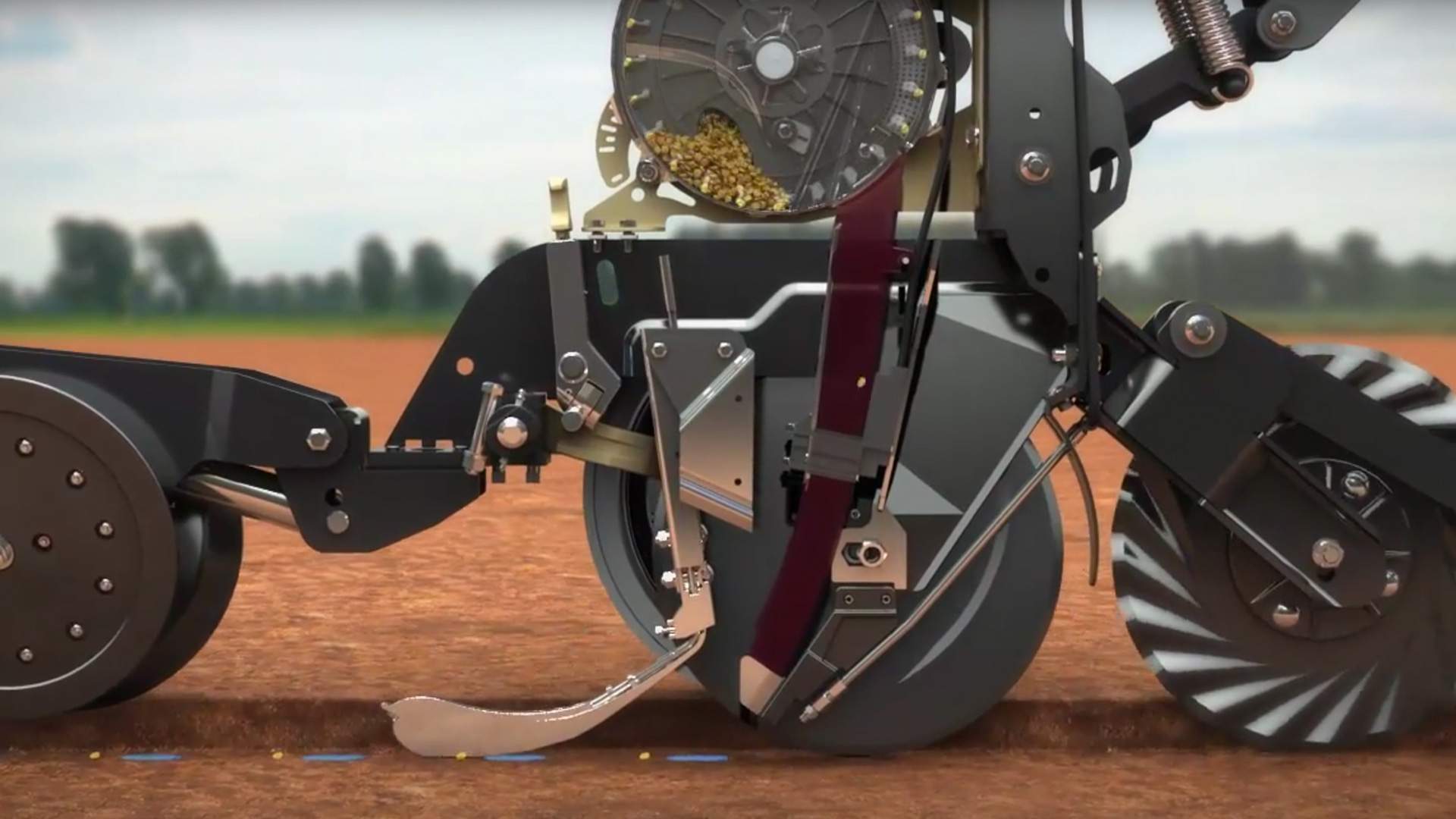

1/4 Great Plains PL5800 Planter

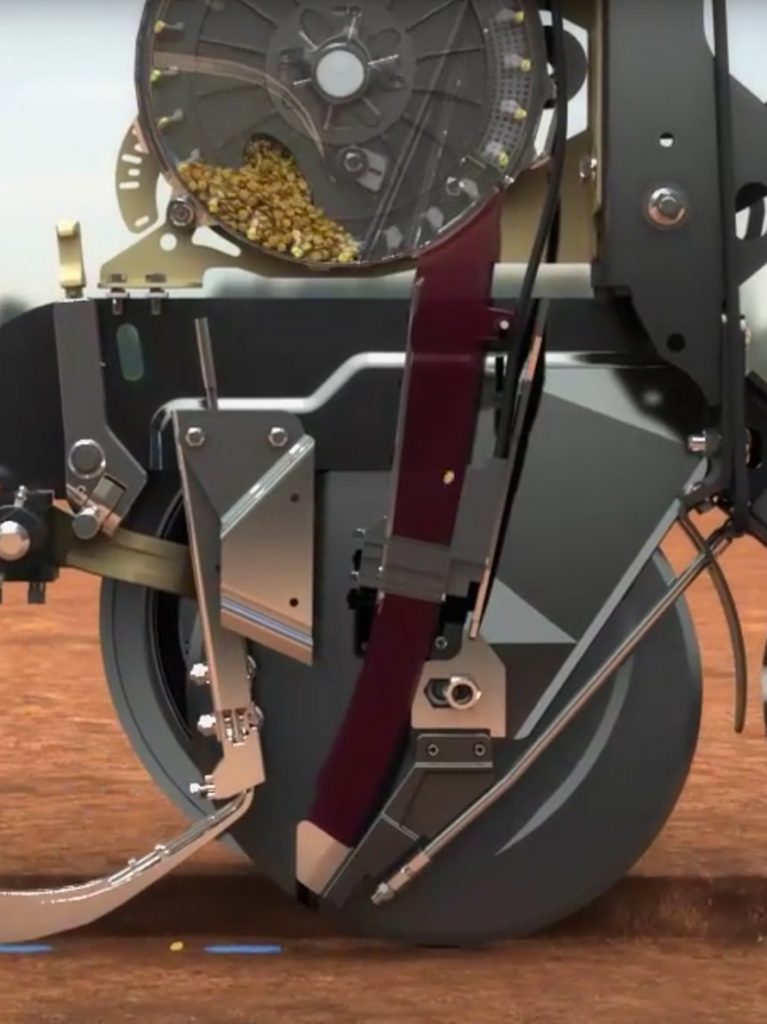

2/4 The AccuShot system places a dose of liquid fertiliser per seed

3/4 The AccuShot control screen offers all the options

4/4 The wireless key fob controls the individual row units from outside the cab

Giving each seed its best shot

The AccuShot attachment can be used on Great Plains PL and YP series planters. It is ISO11783 compatible and you control it from a screen in the tractor cab. On the screen you set the amount of liquid fertiliser and exact distance and position (in front, on top, or behind) in relation to the seed.

The mechanism is simple. Each planter row has a sensor. When a seed passes the sensor, it activates a solenoid valve which shoots a predetermined amount of liquid fertiliser into the row.

There is also a wireless key fob with which you can control the mechanism outside the cab. This is handy when you are turning rows on or off and for checking blockages in muddy areas. This is a low maintenance system with no wear parts and it only requires an end-of-season cleanout.

Because different soils need different treatments, AccuShot allows each farmer to apply their own nutrient mix and dose. Treatments that could harm the seed on contact can be precisely placed behind or in front of the seed. Precision enables savings.

The People

“Multiple years of field testing has shown the consistent benefit of the AccuShot system. Precision placement of starter fertilizer with AccuShot increases yield with reduced starter fertiliser rates. This provides an economic and environmental benefit.”

Blake Bergkamp, Great Plains Agronomist

“The precision of the AccuShot system is also complemented by Great Plains Air-Pro MeterTM and Clear-Shot Seed TubeTM. The consistency of seed placement and spacing helps lead to more uniform emergence and plant stand counts. Additionally, for operations utlilizing prescription based variable rate seeding, AccuShot excels as it maintains an accurate amount of fertilizer per seed. This ensures operators are not under or over applying starter fertilizer as seeding rates adjust throughout the field. This optimizes the agronomic and economic return from the investment of starter fertilizer.”

UN Sustainable Development Goals

The Great Plains AccuShot contributes to the United Nations Sustainability Development Goals of achieving zero hunger, encouraging economic growth, promoting industry, ensuring sustainable development and protecting life on land.

Explore other stories from our brands

How should we address the great challenges of our time? Can we shape a better future together?

The Kubota Group wants to lead the way with innovative solutions for agriculture.

Sustainable, Professional Farming with Mechanical Weeding

Mechanical weeding offers wide agronomic benefits, enhancing soil health, nutrient availability, and plant growth.

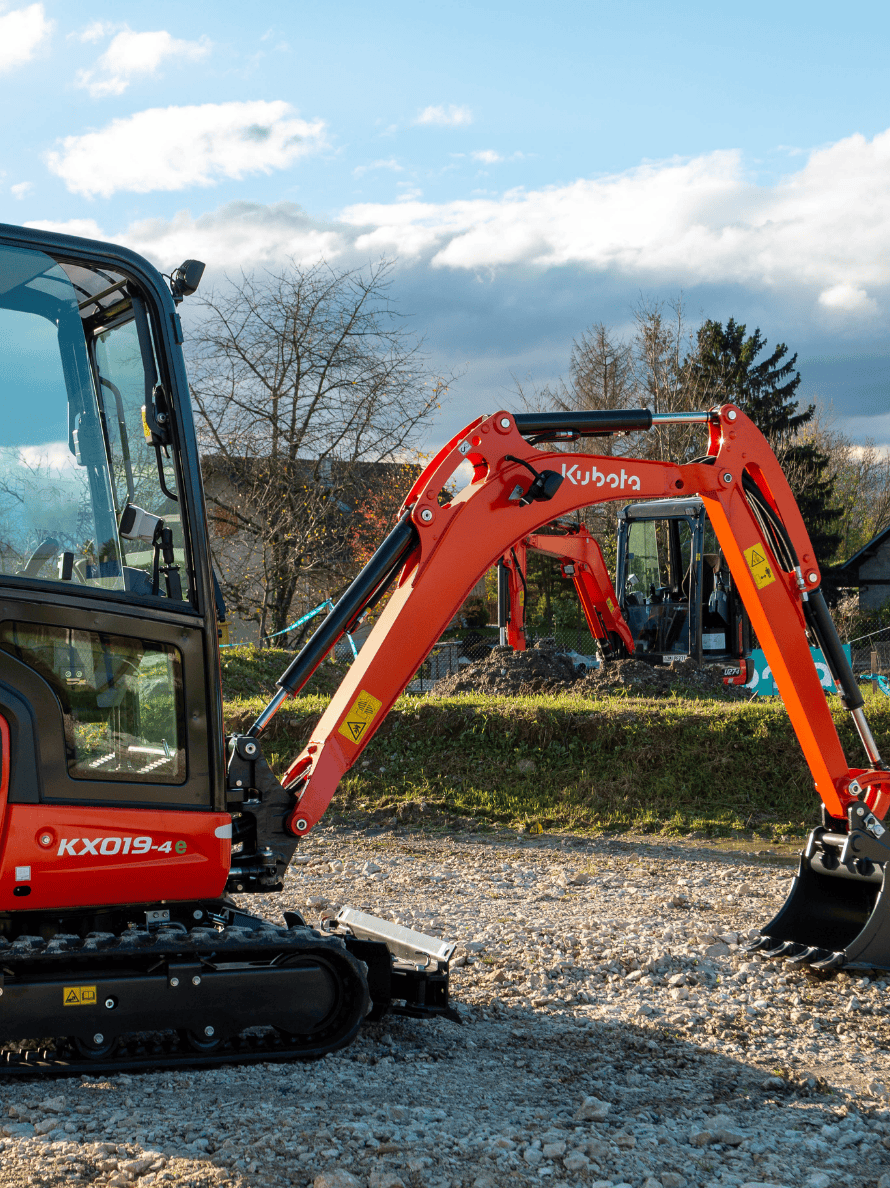

Kubota | Electric Retrofit Kit for Excavators

Electrification enables zero emissions, quieter operations, and stable costs for eco-friendly performance.

UV Boosting | Alternative to traditional fungicides

Plant protection using UV stimulation.

Kubota Engines | Innovative engine solutions

Kubota engine solutions contribute to carbon neutrality

Kubota | Precise Vine Management

Combining crop sensing and state of the art technology in vineyards enhances vine and environmental health while improving crop quality and yield.

Kubota | Electric compact wheel loaders

Kubota electric wheel loaders offer high performance while producing zero carbon emissions.

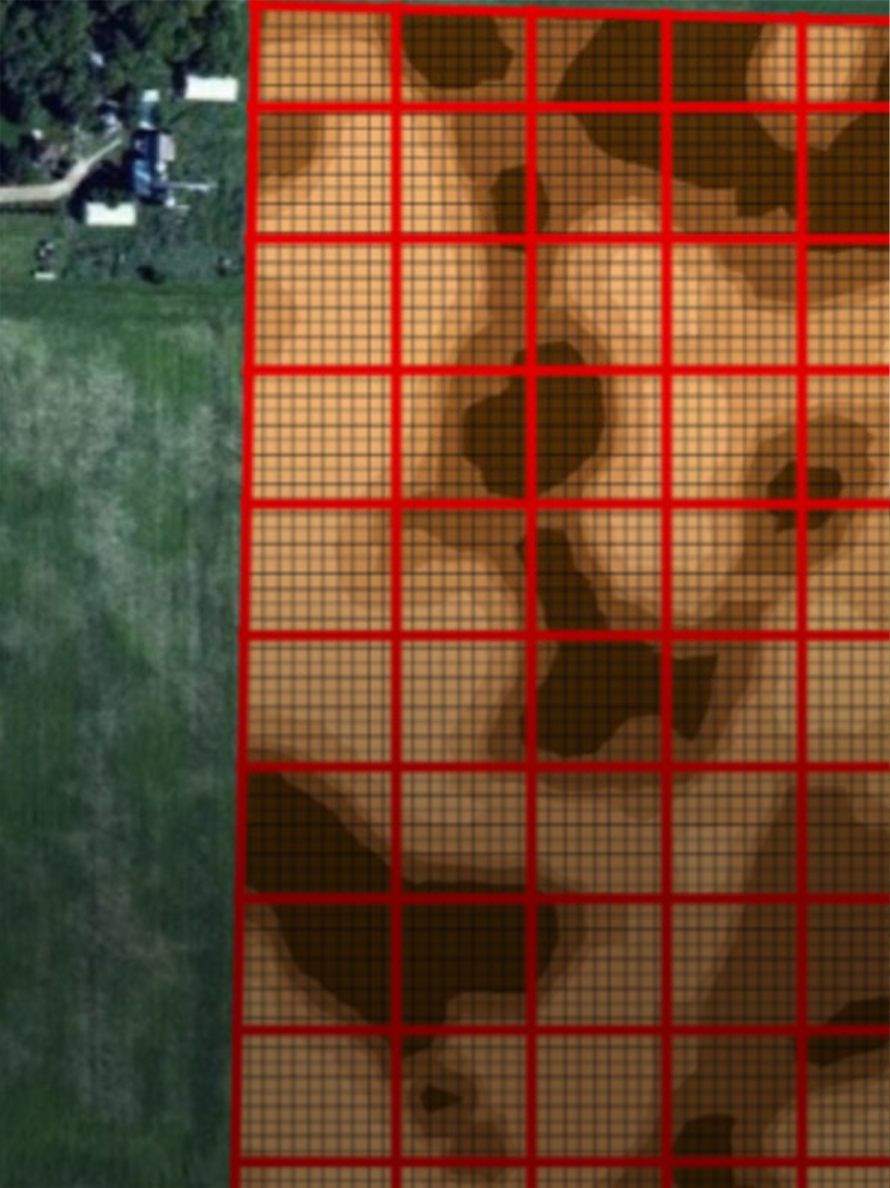

Great Plains | True View – Soil Mapping Solution

Real-time soil sensing detects minute variances in soil content and conditions. Based on this data, soil maps provide a highly accurate field profile.

Kubota | Compact excavator KX38-4e

Building alternatives

Kverneland | PUDAMA

100% yield with 25% less starter fertiliser!

Great Plains | Implement Command

Improving tillage comfort

Kubota | LPG Mini-Excavator

Clean power

Kubota | E-powered Compact Tractor (LXe Series)

The mission: zero emissions

Kubota | Precision Tree Management

Drone imaging for better fruit crops