KVERNELAND PUDAMA

100% yield with 25% less starter fertiliser!

- July 18, 2022

Efficient headstart of plant growth, better root growth, optimized yield, accuracy of fertiliser application, environmental care, cost saving.

The Challenge

How can we ensure high yields of row crops in the most efficient and sustainable way?

When the development of the PUDAMA precision seeder began, in 2017, German farmers were being criticised by the EU authorities and society for using too much artificial fertiliser and slurry. The protection of the environment had become one of the key topics of agriculture. Too much nitrate and phosphorus were contaminating groundwater, causing soil degradation and other environmental problems. During the last two years, this issue has taken a new twist: a shortage of nitrogen and limited resources are driving up fertiliser prices all around the whole world. European regulations, rules and policies have defined new standards and reduced the kinds of components allowed.

What are the benefits of the PUDAMA spot fertiliser application?

- Spot fertiliser application during maize sowing, giving a headstart to the root and plant growth

- Increased sustainability by reduced resources needed

- Environmental care – no overdosing or wash out

- Spot fertiliser application precisely and exclusively next to each seed, maintaining the yield with less input

The Solution

Precision in fertiliser application

Maize is a hungry crop that can require fertiliser application before, during and after planting. In Germany it is common to give the seeds a so-called starter fertiliser. It is usually applied in the form of a continuous band under the maize seed. Researchers were concerned about the gap between the seeds: part of the fertiliser band was not being taken up by the seeds and plants. In other words, fertiliser was being wasted and it ended up polluting the groundwater. This led to a unique development: Kverneland has developed a system that synchronises the fertiliser and seed application more precisely, so that the growing plant reaches and benefits from all the nutrients supplied. Better roots lead to better crop growth and yield.

From farm to fork

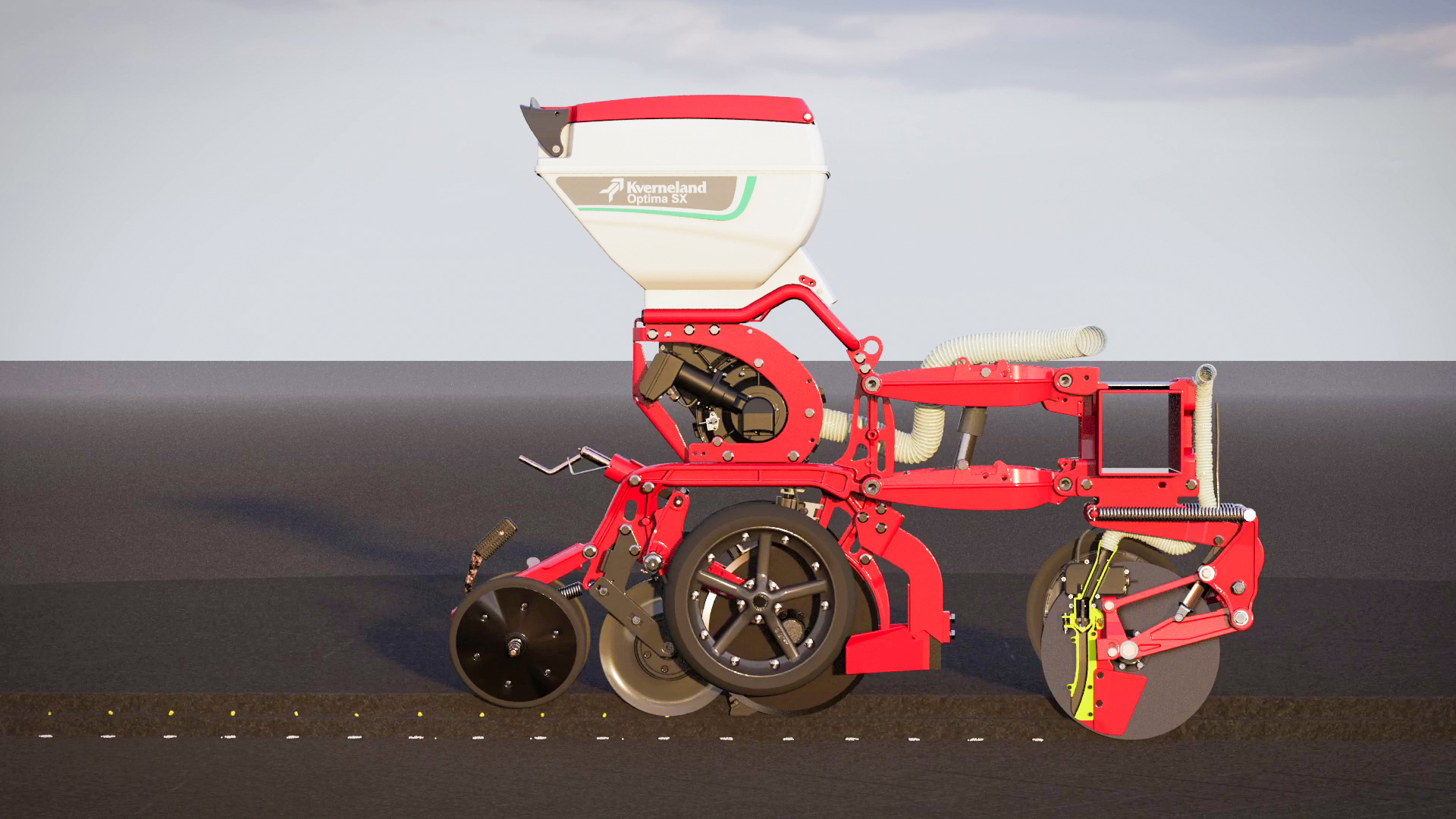

A team was set up by the TH Köln, University of Technology, Arts, Sciences together with Kubota subsidiary Kverneland Group Soest. Funding came from the German Federal Ministry of Food and Agriculture. The project was called PUDAMA, which in German stands for “Punktgenaue Düngerapplikation bei der Maisaussaat” and translates as “Spot starter fertiliser application during maize sowing”.

The objective is all about saving fertiliser, environmental care by reducing resources used, including energy for fertiliser production, while reducing farm production costs and securing food production.

With technology such as the Kverneland Optima TFprofi SX PUDAMA precision drill, farmers can save a lot by reducing fertiliser, transport and work costs. For example, if a farmer with 300ha of maize uses 150kg/ha DAP 18-46 in the conventional way, he would save 37.5kg/ha of fertiliser with the PUDAMA system. This means a saving of 5,625€* for 300ha.

As an example: In Germany up to 81,000 tons of fertiliser could be saved annually in future with the PUDAMA system, which would mean that 16,200 tons less of pure nitrogen and phosphate would be used. This corresponds to a saving of 25 % of the starter fertiliser currently used annually at the same high yield level.

*(Source: index mundi: Price DAP 500€/t May 2023)

Ensuring sustainable food production – a practice example

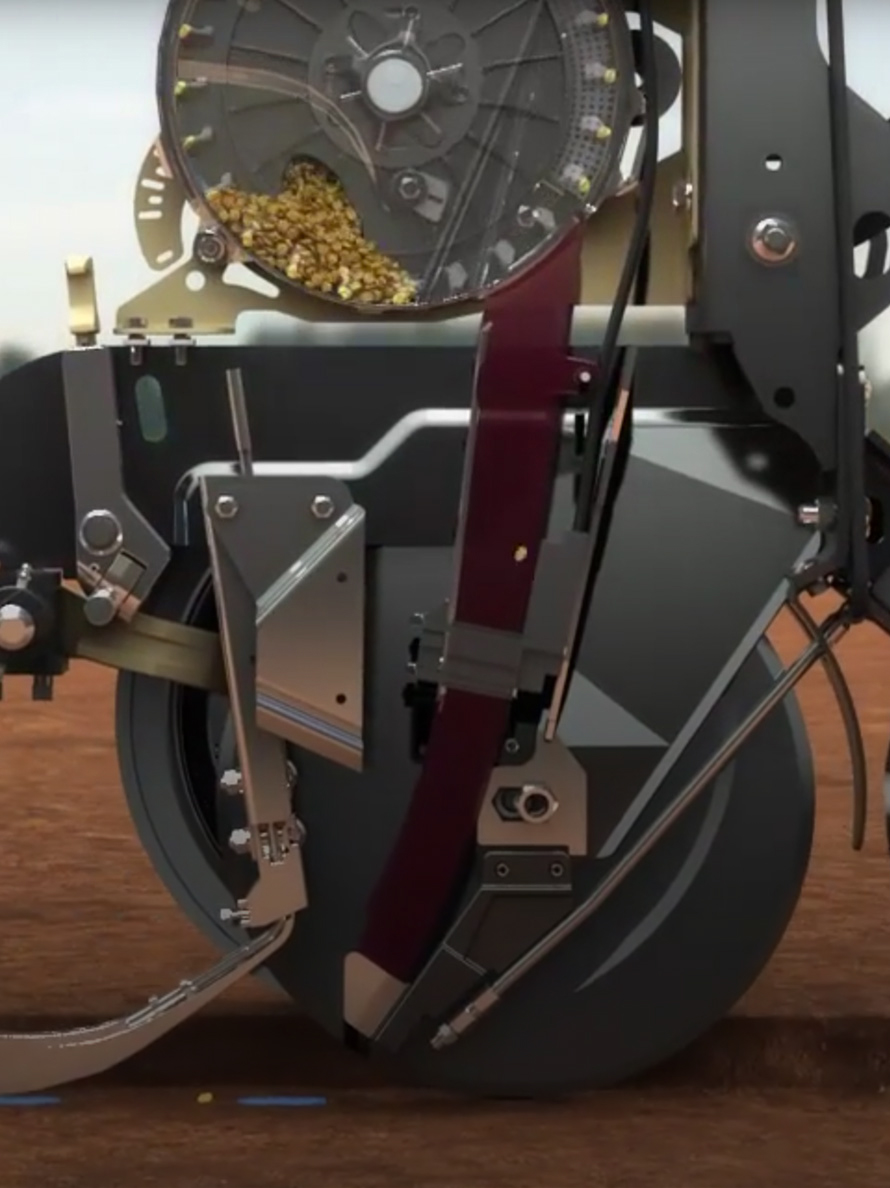

Key for farming now and in the future is to reduce the environmental and climate impact of how we produce and consume food. ‘’Spot fertiliser application’’ means that both seeds and fertiliser are synchronized and precisely placed at very high speed. Precision seeders with the PUDAMA system, place a fertiliser deposit exactly below and next each grain of maize – at a frequency of up to 25 per second. It uses a brush to hold the fertiliser portion and air pressure to release it at the exact moment.

Results: 100% yield with 25% less starter fertiliser

The PUDAMA system has been shown to achieve the same yield as a traditional continuous band of fertiliser – with 25% less starter fertiliser. Unused nitrogen and phosphates are saved and do not washed out into the environment. As well as saving on the cost of fertiliser, farmers would save time and money on transport and handling.

North Rhine-Westphalia Efficiency Award 2021

The PUDAMA system was awarded the main prize in the product category of the North Rhine-Westphalia Efficiency Award 2021. The prize honors innovative products and services developed in the German state of North Rhine-Westphalia. To win, a product has to demonstrate key efficiency factors, such as resource-saving product development, environmentally-friendly manufacture, reduced environmental impact during the product’s life, and recyclability.

Additional awards like at ATH 2022 in the Netherlands, at SOMMET DE L’ÉLEVAGE 2023 or at INNOVE SPACE 2023 followed since then.

The People

“Key for farming now and in the future is to reduce the environmental and climate impact of how we produce and consume food. With PUDAMA, we can save 25% of the starter fertiliser. That means it does not go into the soil and it is not washed out. At the same time, we are talking about saving 81,000 tonnes of fertiliser per year in Germany, fertiliser which does not even have to be produced.”

Volker Schanzenbach, Kverneland R&D Manager

UN Sustainable Development Goals

Explore other stories from our brands

How should we address the great challenges of our time? Can we shape a better future together?

The Kubota Group wants to lead the way with innovative solutions for agriculture.

Sustainable, Professional Farming with Mechanical Weeding

Mechanical weeding offers wide agronomic benefits, enhancing soil health, nutrient availability, and plant growth.

Kubota | Electric Retrofit Kit for Excavators

Electrification enables zero emissions, quieter operations, and stable costs for eco-friendly performance.

UV Boosting | Alternative to traditional fungicides

Plant protection using UV stimulation.

Kubota Engines | Innovative engine solutions

Kubota engine solutions contribute to carbon neutrality

Kubota | Precise Vine Management

Combining crop sensing and state of the art technology in vineyards enhances vine and environmental health while improving crop quality and yield.

Kubota | Electric compact wheel loaders

Kubota electric wheel loaders offer high performance while producing zero carbon emissions.

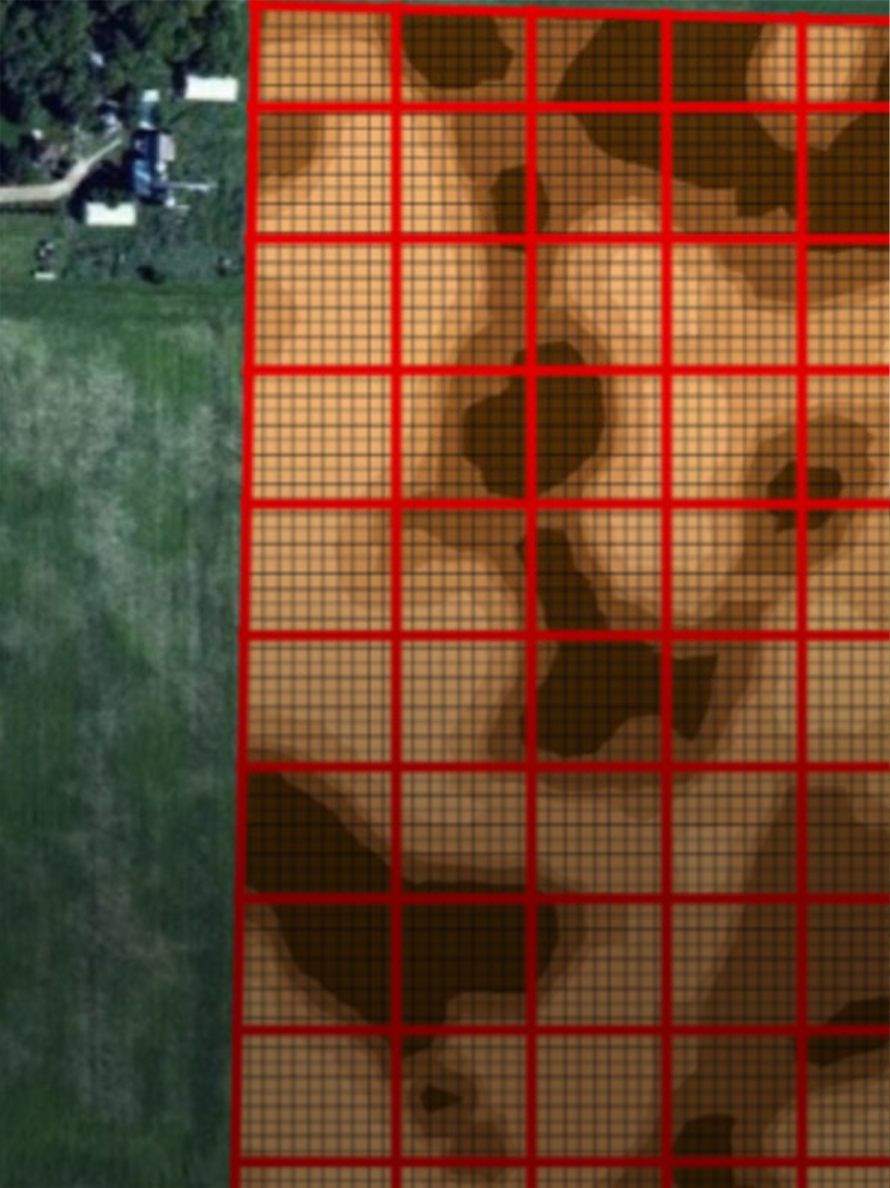

Great Plains | True View – Soil Mapping Solution

Real-time soil sensing detects minute variances in soil content and conditions. Based on this data, soil maps provide a highly accurate field profile.

Great Plains | AccuShot precision seed fertiliser

The best start for each seed

Kubota | Compact excavator KX38-4e

Building alternatives

Great Plains | Implement Command

Improving tillage comfort

Kubota | LPG Mini-Excavator

Clean power

Kubota | E-powered Compact Tractor (LXe Series)

The mission: zero emissions

Kubota | Precision Tree Management

Drone imaging for better fruit crops