PRESS RELEASE

Next step in environmental friendly spraying

Nieuw-Vennep, Netherlands

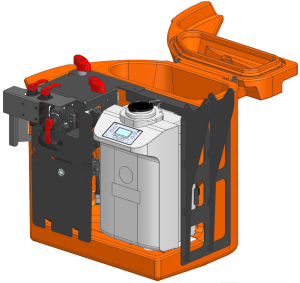

Kubota is introducing some interesting new features on the XTS4 trailed sprayer. Farmers are dependent on nature every day to grow crops and it is part of their business to take care of the environment. With the new features on the XTS4 like an upgrade in tank volumes, iXflow-Pulse – Pulse Width Modulation –, Closed Transfer System and Boom Guide ComfortActive makes Kubota ready for the upcoming legislation and for the next step in environmental friendly spraying.

With the development of growing farm sizes with more fields that are located further away, farmers are more on the road and request bigger tank capacities. With the offering of new tank volumes of 3800, 4500 and even a top model of 5300 litres, the XTS4 trailed sprayer is ready for the future.

The XTS4 has a low centre of gravity and in combination with a steering axle it contributes to excellent stability in different field conditions. The track width can be changed from 1.50 to 2.25 metres in combination with a tank capacity of 3800 and 4500 litres. With 5300 litres tank capacity, a steering axle is possible of 1.80 to 2.25 metres. This ensures maximum steering possibilities with a tight turning radius.

Best crop coverage under changing conditions with iXflow-Pulse

With the new iXflow-Pulse – Pulse Width Modulation – system on the XTS4, in combination with the complete heavy duty HSS spray boom range, the iXflow-Pulse system creates a balance between droplet size, crop coverage and drift. With the result of an optimal droplet size spectrum to reach the desired crop coverage, independent from changing speed or application rate. With iXflow-Pulse it is possible to create a flexible and fast adjustable opening and closing time of the nozzles. When driving faster the opening time will become longer. When driving slower the opening time gets shorter, but by using the iXflow-Pulse the right droplet size will be kept.

During variation in application rate, for example in curves, there is often overdosing and underdosing or during speed variation at start/stop on headlands or slowing down during turning or when driving and spraying up or down the hill. iXflow-Pulse with iXcurve takes care that there is a different output from the inner to the outer boom side, dependent on the boom speed, resulting in an equal application rate in every boom segment. Another benefit is that the pressure and flow can be adjusted separately, and during operation. One nozzle can be used for a wider range of applications, which means less changes of nozzles required, saving time and increasing efficiency. There is also the ability to use lower pressure with the same nozzle in challenging or windy conditions.

An environmental friendly way of filling via a Closed Transfer System

With the integrated Closed Transfer System of the chemical inductor it will ensure a safe and exact way of filling of the product in the right concentration as well as integrated cleaning of housing and container. It will have a minimum risk for both operator and the environment by reducing point source contamination into soil or water surface by limiting the risk of product leakage during filling operation. As well that the complete product is used and the cans are completely emptied and cleaned by the CTS system, so only empty and clean cans are left for recycling.

The chemical inductor of the XTS4 is adapted to integrate CTS directly at the filling station. In this way the containers are directly placed on the CTS housing to allow the products to flow in a controlled way into the sprayer, even if a container volume is only partly needed. The remaining chemical inductor provides users to still have the possibility to safely fill products like powders and granules into the machine. The chemical inductors are equipped with a suction connection to transfer the liquid into the main tank and a pressure connection for clean water to rinse and clean the containers, interface and CTS equipment after use.

Boom Guide ComfortActive

Boom Guide ComfortActive is optionally available as new feature on the XTS4 trailed sprayer. This means automatic boom height control for the complete boom width, which is suitable for flat and mild sloped field conditions. With the two ultrasonic sensors, with integrated roll sensors on the boom, the spray height can be controlled via the central slope correction and boom lift functions. A proportional hydraulic valve is steering the central, hydraulic slope correction cylinder to get the best spraying result in uneven crop conditions and lower driving speeds.

The XTS4 sprayer in combination with these features makes it ready for the future and offer the next step in environmental friendly spraying.

Kubota XTS4 – Specifications in Brief:

| XTS4 | |||

Nominal tank capacity (l) | 3800 | 4500 | 5300 | |

Maximum tank capacity (l) | 4100 | 4750 | 5600 | |

Chemical inductor (l) | 37 | 37 | 37 | |

Clean water tank (l) | 620 | 620 | 620 | |

Hand wash tank (l) | 32 | 32 | 32 | |

Spray boom (m) | HSA 21-33/HSS 18-40/30-24/36-24 | |||

Wheel axle (m) | Adjustable from 1.50-2.25 | Adjustable from 1.50-2.25 | Adjustable from 1.80-2.25 | |

About Kubota

Kubota has been a leading manufacturer of agricultural equipment, construction equipment, lawn mowers and and Industrial Engines since 1890. With its global Headquarters in Osaka Japan, offices in more than 120 countries, and more than 50,000 employees in North America, Europe and Asia, Kubota had a turnover of $20.4 billion in 2022. Although machinery equipment is its main products line, Kubota also produces a wide range of products such as city water purification systems, irrigation systems, piping systems, roof and home construction, and large underground valves.

Our Mission

Our Brand Statement, “For Earth, For Life,” speaks to our commitment to the conservation of the environment while aiding the production of food and water supplies, which are vital to meet the needs of our society, as the world’s population continues to grow. This mission is accomplished every time a Kubota tractor harvests the land to produce food or when our construction equipment excavates to transport water or provide shelter. For more information on Kubota, please visit www.kubota-global.net or www.kubota-eu.com.

Contact

Arable Systems Division – Product Application Specialist

Bert van der Horst

Bert.vander.Horst@Kvernelandgroup.com